- TOP

- SUSTAINABILITY

- FUKUVI's Initiatives

- Development of products using sustainable raw materials (“Free Floor”)

Development of products using sustainable raw materials (“Free Floor”)

Life

Technological Innovation

Partnership

“Free Floor CP Series” with a change to sustainable raw materials (announced in February 2023)

Introducing our "Free Floor CP Series," a versatile dry-type double-layered flooring solution ideal for a range of applications, from detached houses and condominiums to various facilities. We are proud to announce that all bolts used in this series are now crafted from eco-friendly recycled nylon. This nylon is derived from recycled fishing nets, car airbags, and strapping bands, addressing the issue of marine plastic waste. By choosing our flooring, you support efforts to combat marine pollution and reduce CO₂ emissions.

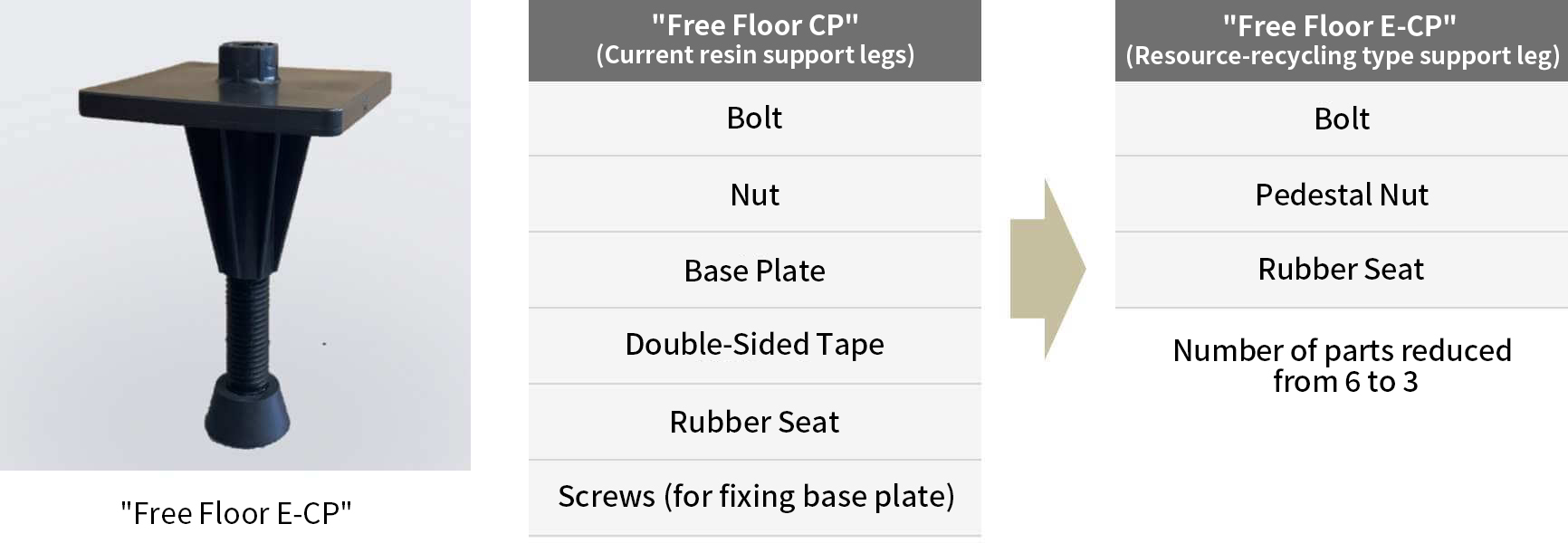

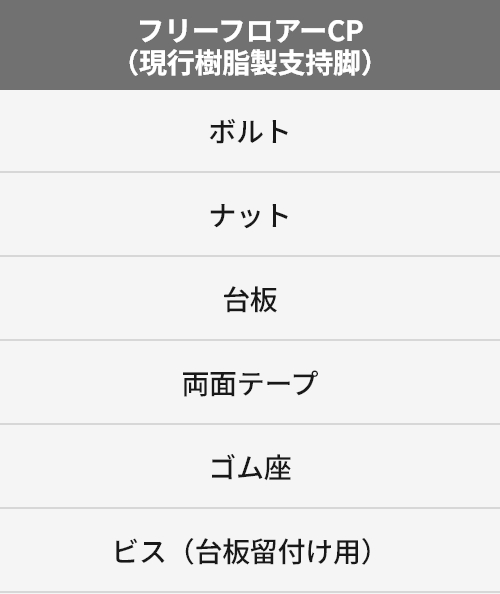

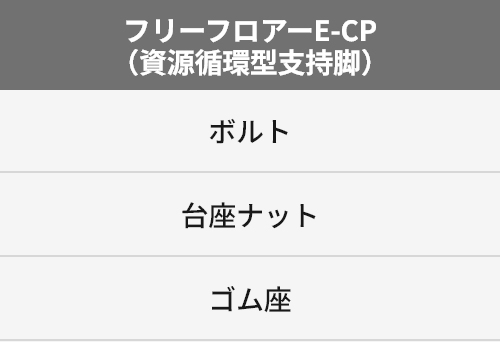

"Free Floor E-CP" with half the number of components in addition to the change to sustainable raw materials (announced in August 2023)

As with the "Free Floor CP Series" above, in addition to using environmentally friendly recycled nylon as raw material, we have developed "Free Floor E-CP" that contributes to reduction of CO₂ emissions by reducing the number of components by half. This product has fewer components than the CP series and requires no adhesives or tapes, making it easy to sort and recycle.

reduced from 6 to 3

CO₂ reduction based on LCA calculation results (compared to our steel support legs)

- Free Floor CPR:About 44.2% reduction*

- Free Floor E-CP:Approximately 60.1% reduction*

Developer Comments

Utilizing the diverse technologies we have cultivated over the years, we will continue to work toward the realization of a sustainable society.

*The calculation results are our calculation results and are not guaranteed values. CO₂ emissions at each stage of the process are calculated by our company using primary data from surveys and IDEAv2.3 as reference. Calculation results are calculated based on the amount of support legs used per 1 m2.

Why did you choose Free Floor for a product whose raw materials are being changed?

In recent years, in response to the growing movement around the world towards carbon neutrality by 2050, we have felt the need to develop products that are more environmentally friendly than ever before. Free Floor has been on the market for over 30 years and is one of FUKUVI's signature products, which has been repeatedly renewed to enhance its novelty. In the dry double-layered flooring industry, there are no environmentally friendly products, so we aimed to make this product a unique feature by making it environmentally friendly.

Why did you choose to use raw materials made from marine plastic waste?

Please tell us about any difficulties or difficulties you faced during development.

REAMIDE®, a recycled nylon raw material from Refineverse Group Co., Ltd., used this time, has never been recycled as a construction material. Because we are reusing fishing nets that have actually been used in the seas around Japan, we have to meet certain conditions, such as keeping the different types of fishing nets above a certain grade, and ensuring the strength and sound insulation of the support legs. I had a hard time setting it up.

Where did you feel a sense of accomplishment?

After development, we received a great response when conducting promotional activities with customers, and we felt that interest in environmentally friendly products is increasing even within the construction industry. At the beginning of development, there were many cases where people did not understand when we talked about SDGs and CO₂ emission reduction, but now people choose products not only considering cost and functionality, but also environmental friendliness. I feel that we have been able to develop products that will lead to the future.